Complete Guide to Hydraulic Hose Selection

Choosing the right hydraulic hose is a crucial decision for many companies that rely on hydraulic systems for their day-to-day operations. It’s important to know that choosing the wrong hydraulic hose can dramatically affect equipment efficiency, safety and longevity by increasing the risk of failures that can lead to downtime and costly repairs. In this guide, I provide you with an overview of what to consider when going through the hydraulic hose selection process, so you can make an informed decision when it comes to choosing the right hose for your application.

Quick Links

Understanding Your Application

Before selecting a hose, it’s crucial to thoroughly understand its intended application. This involves knowing the fluid or substance it will carry, the environment in which it will operate, and the specific requirements of the system it will integrate with. Understanding these factors ensures that the chosen hose meets the performance, safety, and regulatory standards needed for its application.

Using The STAMPED Method

Effective hydraulic hose selection begins with a detailed understanding of your application’s demands. The STAMPED method guides this assessment, focusing on:

- SYSTEM requirements, including pressure, flow rate, and temperature considerations: It’s essential to evaluate the system’s operational pressure, the fluid’s flow rate, and the range of temperatures the hose will be exposed to during use to ensure compatibility and safety.

- TEMPERATURE range, both internal and external: The temperature range a hydraulic hose faces is key to selecting the right material and design. Hoses must handle the application’s maximum and minimum temperatures without degrading. High temperatures can hasten rubber aging and weaken reinforcement, while low temperatures may cause brittleness. Temperature extremes also affect fluid viscosity and system efficiency.

- APPLICATION specifics influencing hydraulic hose selection: The specific application of the hose — whether it’s for heavy machinery or manufacturing and maintenance equipment — dictates the hose choice to ensure optimal performance and compliance with industry standards. Different applications may require hydraulic hoses with various characteristics, such as flexibility, abrasion resistance, or compatibility with specific fluids.

- MATERIAL compatibility with the conveyed fluids: Ensuring that the hose material is compatible with the fluids it will carry is vital to prevent chemical reactions that could lead to hose deterioration, leaks, or system failure.

- PRESSURE requirements, encompassing both working and burst pressure: The hose must be able to withstand the system’s maximum working pressure and have a burst pressure rating high enough to provide a safe margin for unexpected surges or spikes in pressure.

- END fittings needed for the hose: Selecting the correct end fittings (e.g., JIC, NPT, flanges) for the hose is essential for a leak-free connection and compatibility with the existing system components, ensuring easy installation and maintenance.

- DELIVERY of fluid and hose: Delivery ensures optimal fluid velocity and volume in hydraulic hoses for system efficiency. It also encompassed considerations such as managing hose logistics and availability to prevent downtime and delays.

For additional insights on the STAMPED Method, I encourage you to read our blog Factors to Consider When Selecting a Hydraulic Hose.

Environmental Factors of the Application

In addition to STAMPED considerations, environmental factors external to the application like exposure to chemicals, abrasion, and UV radiation must be considered.

- Chemical exposure: The compatibility of hose materials with chemicals they might come into contact with is paramount for ensuring longevity, safety, and performance. For instance, hoses used in chemical processing plants must resist a wide range of corrosive substances.

- Abrasion Hydraulic hoses in dynamic applications, such as those connected to moving parts or used in abrasive environments (like construction sites or manufacturing floors), are susceptible to wear and tear from external abrasion. Materials engineered for high abrasion resistance can help withstand these conditions much better.

- UV Radiation: Continuous exposure to UV radiation can deteriorate many materials over time, leading to cracking, brittleness, and a loss of structural integrity. This is a critical consideration for hoses used in outdoor applications, from pressure washing to aerospace.

As you can see, choosing the right hydraulic hose for your application is very important. However, ongoing maintenance and inspection of your hose is also essential to ensure that it continues to operate safely and efficiently throughout its expected service life.

Matching the Proper Hydraulic Hose Using Specifications

Not all hoses are created equal. Once you’ve determined all the factors of your application, you’ll need to find the hydraulic hose that will meet the specifications of your system and its environment. That’s where hose specifications and advice from hydraulic hose professionals come in.

There are a total of nine key specifications to look for when selecting a hydraulic hose.

Materials

Lists the materials used to manufacture the tube, reinforcement and cover of the hydraulic hose, all of which are important for choosing the right hose.

Temperature Range

Defines the hose’s operational temperature limits, crucial for material selection and application suitability.

Hose Inside Diameter (I.D.)

Influences flow rate and velocity, with larger diameters reducing pressure drop and enhancing system efficiency.

Hose Outside Diameter (O.D.)

Affects installation flexibility and bend radius, critical for routing in tight spaces.

Working Pressure

Indicates the maximum safe operating pressure, essential for selecting hoses for high-pressure systems.

Minimum Burst Pressure

Provides a safety margin, set at four times the working pressure, indicating hose failure thresholds.

Minimum Bend Radius (MBR)

Specifies the smallest safe bending point, affecting installation versatility and hose longevity.

Vacuum

Denotes the hose’s ability to maintain structure under vacuum conditions, vital for certain applications.

Recommended Application & Fluid Compatibility

Ensures chemical compatibility and optimal performance for specified hydraulic fluids and applications.

In addition to these nine specifications, it is important to take into account industry-standard specifications such as SAE and ISO, which play an essential role in the hydraulic hose selection process, providing benchmarks for quality and performance.

To find out more about these specifications, visit our blog dedicated to hydraulic hose specifications.

Knowing About the Different Types of Hoses

Another important factor in hydraulic hose selection is the type of hose. Years of research and development have identified the optimum hydraulic hose specifications for certain types of applications. Today, there are a multitude of hydraulic hose types grouped according to construction, material, and function to meet specific operational challenges. In order to simplify the selection of their hydraulic hoses, some manufacturers such as Gates have even developed a clever family classification system labeled on their product’s covers in addition to key technical specifications.

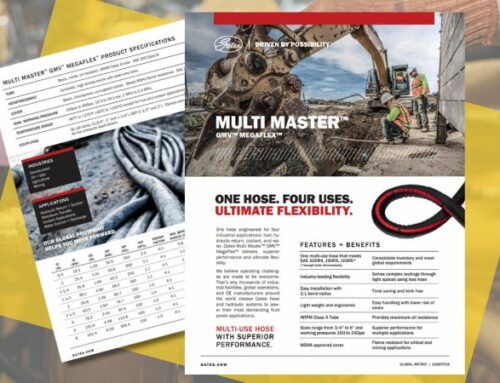

For example, braided hydraulic hoses are widely used in applications where flexibility and strength are essential, such as in construction equipment, mining machinery and industrial machinery. Thermoplastic hoses, on the other hand, are often used in medium and high-pressure hydraulic systems, for handling compressed air and gases, transporting chemicals, and for tasks such as water cleaning and paint spraying. There’s also a category of hoses known as fleet hydraulic hoses, specially designed for heavy vehicles and equipment, where they play a crucial role in braking systems, fuel distribution, facilitating the flow of grease and oil, and so on.

Knowing that these different hose categories exist, and understanding what characterizes them, goes a long way to helping you select the ideal hose for your application. Read our blog on the different types of hydraulic hoses to find out more.

The Potential Risks of Not Choosing The Right Hydraulic Hose

I can’t stress enough the importance of choosing the right hydraulic hose for your application. The consequences of selecting an inappropriate hydraulic hose can be significant and may lead to various issues. Let’s take a look at some of them.

System Inefficiency

An unsuitable hose affects overall system performance, leading to inefficiencies and increased energy consumption. Reduced efficiency not only wastes energy but also compromises the precision of hydraulic operations.

Hose Failures

Choosing the wrong hose can result in hose failures during operation, leading to unexpected downtimes and interruptions in workflow. This directly impacts productivity and efficiency, causing delays in project completion and potentially harming the business reputation.

Damage to Equipment

An ill-suited hose may not withstand the system’s pressure, temperature, or fluid compatibility, resulting in damage to hydraulic components, pumps, valves, and other machinery. Equipment repairs or replacements can incur substantial costs and extend downtime.

Leaks and Fluid Spills

Incorrect hoses are prone to leaks, posing serious risks such as fire hazards, slips and falls, and environmental contamination. Cleanup efforts for hydraulic fluid spills can be time-consuming and expensive and may involve regulatory fines for environmental violations.

Safety Hazards

A hose failure can cause personal injury to operators or nearby personnel due to sudden releases of high-pressure fluid. Escaping hydraulic fluid can penetrate the skin or eyes, leading to severe injuries. Proper safety measures and equipment are crucial to mitigate these risks.

Financial Loss

The combined impact of downtime, equipment damage, cleanup costs, and safety incidents results in significant financial losses for businesses. These losses extend beyond immediate expenses and can impact long-term profitability and sustainability.

To avoid these consequences, it is imperative to carefully consider factors such as pressure rating, material compatibility, temperature range, and specific application requirements when selecting hydraulic hoses. Proper selection ensures optimal performance, longevity, and safety of hydraulic systems, ultimately saving time, money, and resources in the long run.

In Conclusion

Choosing the right hydraulic hose is essential to ensure the efficiency, safety, and longevity of your hydraulic systems. Errors in hydraulic hose selection can lead to operational inefficiencies, hose failure, equipment damage, safety hazards, and significant financial losses.

It’s therefore important to first thoroughly assess your application, using the STAMPED method and considering the environmental factors in which the application will operate. Armed with this information, you’ll be able to choose the hose category and specific hose that best matches your data.

Seeking Help From Experts in Hydraulic Hoses

At Marshall, our hydraulic hose expertise and specialized hydraulic hose assembly and hydraulic hose repair services ensure your system’s reliability. With our focus on customized solutions and extensive inventory, we help reduce downtime and meet operational requirements efficiently. Contact us for expert assistance in hydraulic hose selection to improve your operational efficiency and safety.

Follow Us