The Essentials of PTFE Braided Hoses: Achieving Optimal Efficiency and Durability

PTFE braided hoses (Polytetrafluoroethylene hoses) represent a significant advancement in the field of hydraulic systems, offering unparalleled flexibility and durability in the most demanding environments. In this article, we’ll explore what PTFE hoses are made of, their key benefits and uses, and compare them to standard rubber hoses.

What is PTFE and what is a PTFE braided hose?

PTFE (Polytetrafluoroethylene) is a type of plastic you might know better by the brand name Teflon. Renowned for its slick surface, PTFE boasts exceptional properties such as non-stickiness and resistance to high temperatures as high as 500 degrees Fahrenheit, making it a favorite in both household and industrial applications.

A PTFE braided hose is a formidable hose assembly, uniquely engineered to harness the exceptional properties of Polytetrafluoroethylene and reinforce them with the muscular fortitude of a metal braid. This synthesis of materials creates a hose that is remarkably resistant to high-pressure environments and corrosive chemicals. Like Teflon, a PTFE braided hose is known for its outstanding chemical resistance, temperature resilience, and non-stick surface. These features make it ideal for conveying a wide range of fluids, from standard hydraulic oils to aggressive chemicals, without degradation or contamination.

What are PTFE braided hoses made of?

The anatomy of a PTFE hose is quite sophisticated. At its heart lies a tube of polytetrafluoroethylene, the substance renowned for its slick, non-reactive qualities. This inner tube acts as a smooth conduit for fluids, ensuring minimal resistance and preventing material buildup.

Encasing this tube is a braid of metal, often composed of resilient stainless steel or a comparably robust alloy. This metallic braid is not just a shield against physical abrasions and cuts but also serves as an armor against the rigors of extreme pressures. The interwoven metal provides a flexible yet strong exoskeleton, allowing the hose to maintain its shape and integrity under stress while also enabling it to bend as needed for various applications. This dual composition of PTFE and metal is meticulously designed to meet the demands of strenuous industrial tasks, ensuring that a PTFE braided hose is a synonym for reliability and longevity in challenging environments.

What are the key benefits and properties of PTFE braided hoses?

PTFE hoses, with their array of impressive capabilities, stand as a pinnacle of engineering in fluid dynamics. Below is an overview of the key benefits and properties of PTFE braided hoses.

1. Wide temperature compatibility

The temperature resistance range of PTFE braided hoses is one of their outstanding attributes. Indeed, the majority of PTFE hoses can withstand temperatures as low as -65°F (-54°C) and as high as +400°F (+204.4°C), in some cases as high as +450°F (+232°C). Even when subjected to these extreme temperatures, PTFE hoses can maintain their structural integrity and performance. However, both the maximum temperature and desired operating pressure must be taken into account when selecting the right PTFE braided hose and size for the application. The ability to withstand a wide range of temperatures, while taking operating pressure into account, makes PTFE hoses highly versatile in a variety of industrial applications.

2. Chemical resistance

PTFE braided hoses’ chemical resistance is as equally remarkable as its low- and high-temperature resistance. PTFE hoses can withstand a wide range of chemicals, including aggressive acids and alkalis, which would otherwise degrade ordinary hoses. This resistance ensures a longer lifespan and safer operation in chemical processing plants and other hazardous environments.

3. Non-adhesive quality

The non-adhesive quality of PTFE tubing allows substances to circulate without adhering to the inner walls, facilitating smoother, more efficient transport of materials. For example, PTFE hoses can handle substances such as adhesives, dyes, greases and even more. This non-adhesive quality also makes cleaning easier, as residues can be rinsed away with minimum effort.

4. Purity and non-contaminating nature

In terms of purity, the non-contaminating nature of PTFE is essential for industries where contamination is a concern, such as food and beverage or pharmaceuticals. The material does not leach into or taint the substances it carries, thereby preserving the integrity of the transported fluids.

5. Flexibility and shock resistance

PTFE braided hoses are renowned for their flexibility and shock resistance. They can endure jarring movements and vibrations without sustaining damage, ensuring continuous operation under dynamic conditions. This flexibility also allows for the hoses to be installed in complex configurations where rigid pipes would not be feasible.

6. High flow rates

Designed for high flow rates, PTFE hoses can handle rapid fluid movements, reducing downtime and improving efficiency. The low coefficient of friction and anti-adhesive properties of PTFE braided hoses ensure a continuous lower pressure drop during operation with good pressure rating and full vacuum.

7. Lightweight design

Despite their durability, PTFE hoses are surprisingly lightweight, which simplifies installation and handling, particularly in applications where weight is a critical factor.

8. Durability and economic efficiency

Resistant to deterioration, PTFE braided hoses often exceed their expected service life, offering an economical solution over time by reducing the frequency of replacements.

9. Steam compatibility

PTFE braided hoses are moisture-resistant and rated for steam up to 250 psi at 406°F, and feature low volumetric expansion. This compatibility with steam makes them ideal for sterilization processes and various scenarios requiring steam transport, further demonstrating their versatility and robustness in industrial applications.

What are PTFE braided hoses used for?

PTFE hoses are a mainstay in a multitude of demanding industrial sectors.

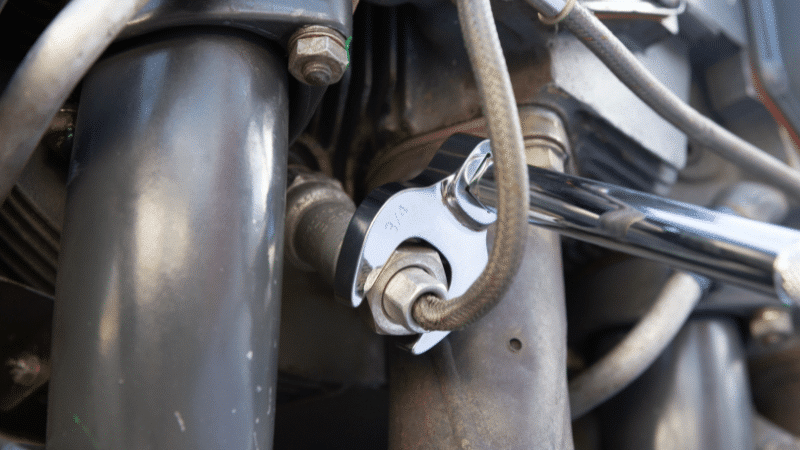

- In the transportation and automotive industry, they are essential for fuel, oil, and brake line systems, where durability against high pressures and reactive substances is critical.

- Aerospace applications rely on PTFE hoses for their ability to maintain integrity in extreme temperature fluctuations and pressurized conditions.

- Within chemical processing plants, these hoses manage the safe transport of corrosive materials, standing up to the harsh substances without degrading.

- In the food sector, PTFE’s non-reactive and clean properties ensure that stringent hygiene standards are met, making them perfect for handling edible products without fear of contamination.

Each of these industries benefits from the unique combination of resilience, reliability, and safety that PTFE hoses provide.

PTFE hoses vs rubber hoses

Compared to traditional rubber hoses, PTFE hoses represent a significant advancement, bringing unparalleled attributes to the forefront of industrial applications. Where rubber hoses falter, PTFE hoses thrive, particularly in environments that demand resistance to extreme temperatures and exposure to harsh chemicals. The resilience of PTFE hoses extends beyond mere durability; they exhibit remarkable longevity, often outlasting their rubber counterparts by a considerable margin, which translates into cost savings and reduced maintenance.

In summary

In settings where both chemical resistance and the ability to withstand high pressure are non-negotiable, the PTFE braided hydraulic hose emerges as the superior choice. The unique braiding technique fortifies the hose, ensuring it holds its shape and maintains performance even under the stress of high-pressure scenarios. This makes them indispensable in industries such as pharmaceuticals, where purity and precision are paramount, or in the oil and gas sector, where every component must resist corrosive substances and operate flawlessly under pressure. The robustness of PTFE hoses ensures a consistency of performance that is critical for the safety and efficiency of these challenging environments.

Marshall Equipment offers a selection of hydraulic hoses as well as hydraulic hose assembly for a variety of applications where space and chemical corrosion resistance are paramount. Our experts will be happy to help you choose the PTFE braided hose that will maximize your application’s performance. Contact Us if you have any questions about our PTFE hoses and services.

Follow Us