7 Key Hydraulic Hose Selection Factors

When it comes to working with hydraulic systems, hydraulic hoses are their lifelines, carrying high-pressure fluids to power various machines and equipment. Understanding hydraulic hose selection factors helps you choose the right hydraulic hose, which can mean the difference between smooth operation and costly downtime due to premature hose failure, reduced efficiency, or even safety risks.

Let’s explore the key factors to consider when selecting a hydraulic hose and discuss the importance of service life and maintenance for optimal performance.

Factors to Consider When Selecting a Hydraulic Hose

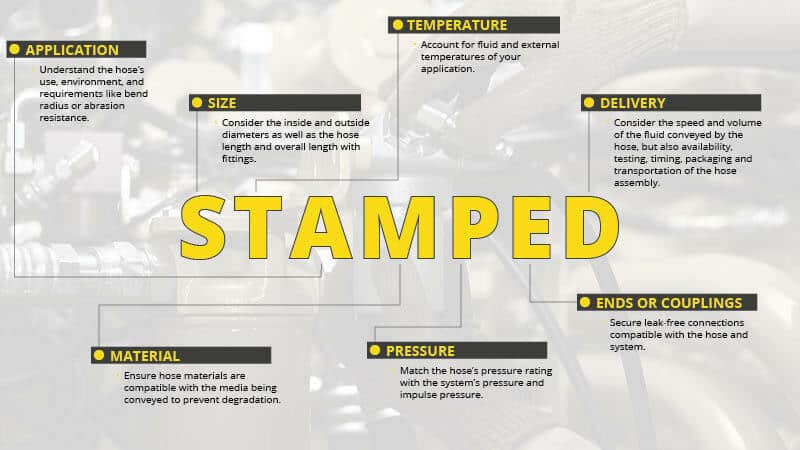

When selecting a hydraulic hose, remember the acronym “STAMPED”. Use it as a checklist to select the right hose assembly for your application.

STAMPED

S = Size

T = Temperature

A = Application

M = Material

P = Pressure

E = Ends or couplings

D = Delivery (volume and velocity)

1. Size

The size of a hydraulic hose is not just about its physical dimensions; it also includes the inside diameter (I.D.), the outside diameter (O.D.) and the overall hose length.

The inside diameter determines the flow rate and pressure capacity of the hose. Choosing the right size is critical to ensure that the hose can handle the hydraulic fluid flow and pressure required for your specific application. Using a hose with a diameter that is too small can result in flow restrictions, increased pressure drop, and reduced system efficiency while using a hose that is too large can lead to excessive fluid heating and energy loss.

In addition to the I.D., the hose outside diameter (O.D.) can also be a critical factor when clamps are used, or when pipes are routed through bulkheads.

Some of the questions to ask yourself when selecting the right size include:

- What is the inside diameter (I.D.) of the hose needed?

- What is the outside diameter (O.D.) of the hose needed?

- What should be the length of the hose required?

- What should be the overall length of the hose, including the fittings?

2. Temperature

Temperature is also another important hydraulic hose selection factor. It significantly affects the longevity and efficiency of hydraulic hoses, with each hose having precise maximum temperatures typically between 200°F (93° C) and 300°F (149° C). In addition, different materials, such as specific compounds and PTFE (polytetrafluoroethylene), have varying temperature tolerances ranging from -65°F (-54° C) to 400°F (204° C).

Careful selection of the right hydraulic hose for the temperature dynamics of your application is crucial. High temperatures can accelerate hose degradation, reducing service life by up to 80%, leading to premature failure. Conversely, low temperatures can induce rigidity and make the hose susceptible to cracking. A complete understanding of the operating temperature range of your hydraulic system is key to ensuring the optimum selection and lasting effectiveness of hydraulic hoses.

Some of the questions to ask yourself about temperature include:

- What is the temperature of the fluid being conveyed?

- What are the external temperatures that the hose will be exposed to?

- Will the hydraulic hose be exposed to extreme heat or cold frequently?

- What are the minimum and maximum temperatures created by the system itself?

3. Application

The specific application of the hydraulic hose is another critical factor in selecting the appropriate hydraulic hose assembly. Different applications may require hoses with various characteristics, such as flexibility, abrasion resistance, or compatibility with specific fluids. For example, a hydraulic hose used in construction machinery may need to be highly abrasion-resistant, while a hose in a food processing application should be food-grade and non-toxic. Understanding the unique requirements of your application is essential for making the right choice.

When considering the application, here are questions you should ask yourself:

- Where is the hose going to be used?

- What material will the hose convey?

- What type of equipment will the hose be attached to?

- What would be the environmental conditions of the application?

- What are the working and surge pressures the hose must withstand?

- Is the hose for a suction application?

- Is the hose compatible with the fluid it will carry?

- Does the hose need to meet any government and/or industry standards, like USCG, FDA, or FMVSS?

- What is the minimum bend radius for the hose?

- Will the hose face excessive abrasion?

- How long is the hose expected to last?

4. Material

The materials used in the construction of hydraulic hoses are vital for their performance and durability. Hydraulic hoses are typically made of layers of rubber or thermoplastic materials reinforced with high-strength fibers or metal wires. The choice of materials depends on factors like the type of hydraulic fluid, temperature, and pressure. It’s vital to ensure that the hose materials are compatible with the hydraulic fluid used in your system to prevent chemical degradation and leakage.

Questions to ask yourself about materials:

- What product of fluid will the hose convey?

- Is the substance considered to be abrasive, corrosive or hazardous?

5. Pressure

Hydraulic systems operate under high pressure, and the hydraulic hose must be capable of withstanding the pressure generated within the system. In addition to all previously mentioned hydraulic hose selection factors, it’s important to consider the maximum working pressure, which is the highest pressure the hose can safely handle. Using a hose with a lower pressure rating can lead to catastrophic failure, posing significant safety risks. On the other hand, using a hose with a higher pressure rating than necessary may result in increased cost and unnecessary weight.

Questions to ask yourself about pressure:

- What is the maximum working pressure of your system?

- Is the hydraulic system static or dynamic?

6. Ends or Couplings

Hydraulic hose fittings, also known as ends or couplings, are crucial components that connect the hose to the rest of the hydraulic system. Choosing the properly matched fittings is essential to ensure a secure and leak-free connection and to maintain the integrity of the hydraulic system The type of fittings you need depends on factors like hose size, thread type, and application.

Some questions about ends and couplings:

- What kind of ends or fittings will be needed?

- What will the thread be connected to?

- Is the required thread compatible with the type of hose and application?

7. Delivery

For Gates, delivery relates to the velocity and volume of fluid conveyed through the hydraulic hose. Velocity, crucial for optimal system performance, impacts the selection of the hose inside diameter, as it must accommodate the fluid speed and volume, ensuring the hose meets operational demands and maintains the system’s efficiency. Selecting the appropriate diameter is pivotal for balancing velocity and volume, sustaining the effectiveness of the hydraulic system.

For other sources, delivery encompasses considerations regarding the availability, testing, timing, packaging, and transportation of the hose assembly, ensuring it reaches the end-user promptly and in optimal condition to prevent system downtime. Whether the product is widely available or unique can impact delivery time, potentially necessitating exploring multiple options to secure flexibility and avoid delays from scarce or discontinued components.

The delivery also involves adherence to specific testing, certification, quality, and potentially special packaging and shipping requirements, according to standards like USCG, CRN, CGA. Quick delivery is pivotal, especially when certifications, tests, or special installations and assemblies are required, allowing for the necessary preparations to maintain consistent operation of hydraulic systems.

Questions to consider about delivery when selecting a hydraulic hose are:

- What is the required fluid volume flow?

- What is the availability of the hydraulic hose?

- When and where do you need the hose?

- Does the hose require special handling and shipping?

In Conclusion

Selecting the right hydraulic hose and fitting is a critical component in ensuring the efficiency and longevity of hydraulic systems. When researching the right product for your application, it is essential to consider all hydraulic hose selection factors including size, temperature, application, material, pressure, ends, and delivery. Each of these elements plays a pivotal role in the functionality and reliability of the hydraulic hose, affecting its service life and the overall performance of the hydraulic system. By carefully considering these factors and asking the right questions, users can mitigate the risk of premature failure, maintain system integrity, and ensure smooth operation.

Find out more about what goes into selecting a hose in our comprehensive guide to hydraulic hose selection.

The experts at Marshall Equipment can help you select the right hydraulic hose for your application. Thanks to our extensive inventory of hydraulic hoses and fittings, we’re able to respond quickly to the needs of many industries, such as construction, food and beverage, transportation and more. Learn more about us by visiting our products and services pages.

Follow Us